Compressed air installations

Also referred to as a compressed air system, a technological transmission pipeline used to distribute the medium - compressed air in specific quantities, times and pressure from the compressor (production site) to receipt points.

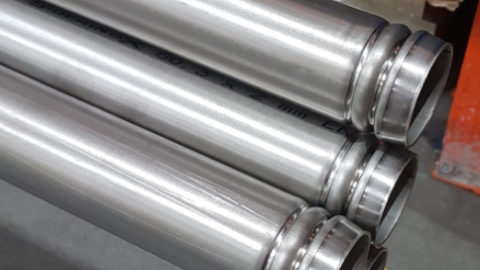

Compressed air installations can be made of:

- stainless steel - Standard OGS system for stainless installations.

- thin-walled stainless steel - System Victaulic Strength Thin 100

- galvanized black steel - Standard OGS system

Advantages of grooved system installations:

- Easy and quick installation, ca. 50% time saving

- Reduced installation downtimes

- No high temperatures or open fire

- No anti-corrosive protection required

- No weld x-rays

- Vibration and noise damping

- Connection tightness (self-tightening)

- Reduced installation downtimes

- No highly qualified staff required

- Fully dismantlable system, reusability option

- Complete systems, connectors, fittings, fixtures, expansion joints

- No tube weakening